Anatomy of a Stylus:

Reservoir/Tip (Non-electric)

Anatomy of a Stylus:

Reservoir/Tip (Non-electric)

We’ve discussed the parts of a stylus. But what do the various parts do?

As I noted, all standard styluses are basically composed of two parts: a metal wax reservoir with writing tip, and a handle (generally wooden or plastic). In the traditional styluses, the reservoir is attached to the handle either by wrapping with wire, or with a wire hook. In the electric styluses, the reservoir is set into the heating element, which is the upper extension of the handle.

(Non-standard styluses–calligraphic pens and drop-pull styluses–will be discussed in depth separately on their own pages.)

Reservoir/Writing Tip: since a stylus is simply an instrument for writing with wax, the reservoir/tip is the business end of it. The reservoir holds the molten wax; the writing tip allows the wax to flow in a controlled manner from the reservoir, much as ink flows from a pen. The size of the opening in the tip determines the width of the written wax line.

Traditional type styluses (i.e. non-electric) use three types of wax reservoirs in their construction: the traditional cone, and two types of modern machined heads.

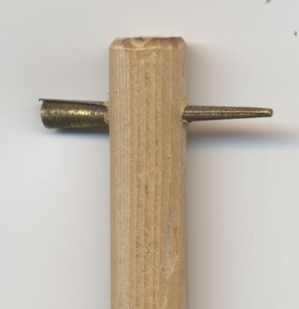

Traditional Cone: The reservoir and writing tip are made of metal, traditionally copper or brass. A small piece of the metal would be cut from a sheet, and either simply rolled into a cone, or cut into the proper shape and then the tip attached into a cone. In the first case, the cone was either placed into a notched stick of wood, or through a small hole drilled through a stick of wood. In Ukraine, styluses are still made this way, as in this example from Kolomyia:

This sort of stylus is used with molten wax; the stylus itself is never heated in a flame, but merely dipped into already liquid wax.

It would then often be secured to the stick by wrapping with wire, horsehair or even string. Examples of that sort of stylus tip can be seen here, in this selection of modern diasporan styluses:

This is a very simple stylus, with a simple copper cone secured with a bit of wire.

This simple stylus also has a simple copper cone, but it is attached with much wrapping of a fine copper wire. This stylus is sold by the Ukrainian Gift Shop.

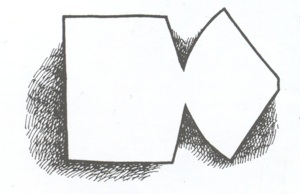

The other type of tip didn’t require notching or drilling the stick/handle. A piece of this shape was cut from a sheet of metal

and one end rolled into a cone. The other end was placed against the handle, and attached by wrapping it around the handle, as you can see in this drawing:

(both drawing are taken from Vira Manko’s Ukrainian Folk Pysanka). If the non-cone bit of metal was cut more narrowly, it could be bound to the handle instead by wire, as in the example below:

In this case, the cone sits on top of the handle/stick. You can see an extension coming off of the bottom of the cone and then curving down around the handle. Wire (copper in this case) is used to attach the metal more securely to the handle.

Newer Ukrainian made styluses have kept the simple metal cone reservoir, but used more modern methods of attaching it to the handle, as you can see here. In all these examples, a metal cap is placed on the stick to hold the reservoir in place.

In this example, the metal cone reservoir is actually welded to a cap, and then that cap placed on the stick/handle.

In this example, a metal cap is placed on the handle, and then a hole is drilled through it and the handle. The reservoir is placed through the hole and soldered in place.

The soldering can be seen better in this example, on the right half of the cone.

This variant also used a metal cone soldered to a metal cap. The manner of soldering is a bit different, though.

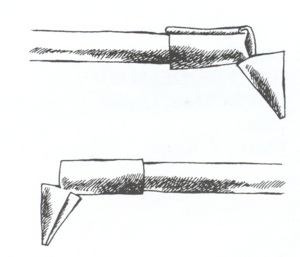

Modern Funnel: Newer North American-made styluses take advantage of modern technology and use machined heads. These are made of heavier metal than the simple cones above, and thus hold heat and resist deformation better. The earlier styluses of this sort generally had specially made heads machined from brass.

This is the reservoir of a so-called “Delrin” stylus. Delrin is the type of plastic in the handle. The stylus itself was created originally by a pysankar named Volker from Michigan. He was the first to use a machined head of this sort (as opposed to the simple metal cones above) and to attach it with a wire to a plastic handle of this sort.

This is a copy of a Delrin stylus made for me by my father, a tool and die man. It was a pretty good stylus for its time (the mid 70s), and I used it to make a lot of my early pysanky.

This is a stylus of uncertain provenance. It uses a machine head similar to that of the “Delrin” stylus, but has a metal cover over the end of the handle.

Modern Tube: The newest non-electric styluses have been developed as an offshoot of electric stylus technology. They use the heads developed for electric styluses, but attach them to traditional (albeit plastic) handles.

This is the “Almost Electric” stylus from WaxArtSupply. It uses a Leroy tip embedded in a solid brass handle tip. The metal of the end of the handle retains head well, keeping the wax within the reservoir molten longer than more traditional non-electric styluses.

This stylus is Eggcessories non-electric version of their better know electric stylus. It uses the same tips as their electric styluses do, attached to the handle with this metal end.

Back to Main Styluses page

Back to MAIN Pysanka home page.

Back to Pysanka Index.

Search my site with Google

The Parts of a Stylus and Their Functions:

The Reservoir/Tip (Non-Electric)